By the tanning type

Tanning - one of the main processes in the leather manufacturing

There are several types of tanning:

- Compounds of chromium (chrome tanning),

- Fats of various fish and marine animals (fatty tanning),

- Extracts of tree species (vegetable tanning),

- Combined tanning (tanning several different substances simultaneously or in sequence, such as chromium compounds and tannins (hromtannidnoe tanning), or in combination with synthetic and artificial tanning agent, zirconium, aluminum, tanning amino, formalin and other tanning agents).

- Impregnation of alumina salts (mineral tanning).

Tanned leather is a process of soaking its fibers tannins. Tanning is carried out or extremely slow saturation of the hide a weak solution of tannin, both extracted from willow bark, oak in the same vat, or maceration of pelts in a strong solution tannin beverage prepared in advance in the form of special extracts from tropical tanning plants. At the beginning of XX century extended soaking the hide is not vegetable substances, and mineral salts, namely, chromium compounds (chromium tanning). Soaking pickling alum and salt leads to the manufacture of special types of leather. For impregnation of the leather fat and blubber are special varieties, such as suede.

The regularity and rapidity of penetration of tanning substances in the semi-finished products depends on several factors: the type of raw material, the nature and mode of preparation of tanning solution, the concentration of tanning substances, tanning solution temperature, time and nature of tanning of the mechanical effects.

The process of tanning is divided into several operations:

The purpose of the first operation - the removal of excess fat from the leather, balances the muscles, films and hair.

The second type of operation - self tanning - gives golyu view this leather by soaking tannins, fat, through painting and so on.

Removing hair from the hide is performed by ashing, acting on the leather of lime and ash or sodium sulphide. This corroded hair follicles in the leather and hair can then be removed by scraping. After ashing leather thoroughly washed and soaked in special acid solutions capable of dissolving the last traces of lime from the skins pores.

Final stage includes the following processes:

Dyeing, rolling, pressing, stamping, printing plastic coating, lacquer, polished face, causing the wax, giving light, giving the water resistance, fire resistance, resistance to pollutants, etc.

Examples of different types of tanning:

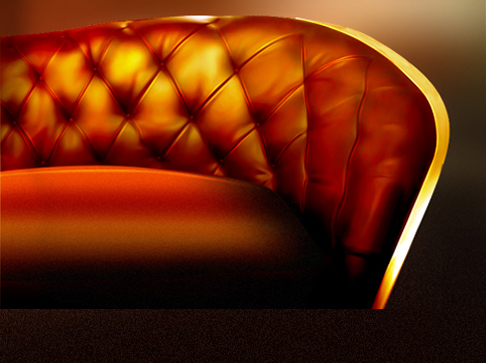

Morocco leather - leather from goat skins vegetable tanned, light-fat and brightly colored.

Velour - made from leather with the front surface defects, chrome tanned, trimmed from bakhtar side to the velvet using a special grinding.

Suede - leather from skins of moose, caribou, wild goats, etc., fatty tanning; face is bakhtar; pile of thick but not fluffy and without gloss, the leather is soft, with a poor absorption of water.

Shagreen - soft vegetable-tanned leather from the skins of sheep or goats, has a nice small relief pattern.

Kidskin - leather from the skins of sheep, goats, dogs, tanning with alum with salt, flour and egg yolks, the leather is soft, thin, used for the manufacture of gloves.